Product display

For more details, please call

customer service

+86 23-68460375 +86 23-68460376Or message

Message

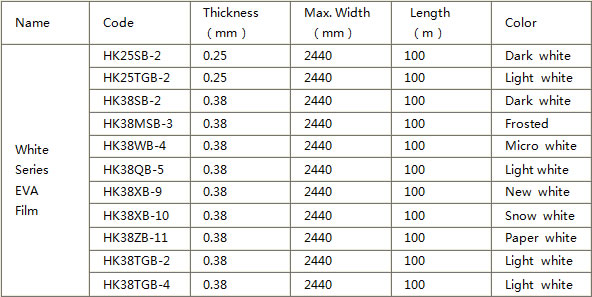

Available products

Production process (for reference only)

To ensure product quality, the molding process is best carried out in two steps:

The first step: Set the temperature at 60-65 degrees, and then keep it for 20-30 minutes after reaching this temperature. The purpose is to achieve the effects of "exhaust" and "dehumidification" while softening the film;

Step 2: Set the temperature between 90 degrees and 95 degrees (depending on the specific situation), and then keep the temperature for 30-40 minutes, then let it continue to maintain vacuum in the furnace and naturally cool to about 60 degrees. And then the finished glass can be taken out.

Special Note

This reference process is based on a single-layer molding machine, and produces a 5 mm double-clip color transparent film glass as a production factor. The temperatureset is the surface temperature of the glass in the molding machine.

Different molding equipment (mainly different internal space size, different heating methods, different positions of temperature probes), different interlayer materials and back film, and production time in winter or summer (mainly different ambient temperature) will all effect the quality of products. Because of the changes in production factors, to ensure the product quality,the processing technology must be appropriately adjusted accordingly.

Although colored film is also a kind of adhesive film,but it is added with a certain amount of "dyeing" material during the production process. Therefore, compared with the colorless transparent film, the intensity should be relatively weak. The deeper the concentration of color film (such as opaque color film), the weaker the bond strength, and properly increasing the molding temperature of color film is an effective way to improve the bond strength. However, the molding temperature cannot be improved uncontrollably. Under the high temperature, colored film may have chromatic aberration, blistering . In addition, the interlayer materials with different thicknesses and the surface properties of the interlayer materials are different, and the processing temperature setting must be properly adjusted; therefore, it is recommended that the customer must understand the material characteristics before using the colored film or other different interlayer materials to set the right production process.

Regarding the process of clamping the wire glass, also need to pay attention to the environmental humidity. Excessive humidity will cause film, silk material and glass to show a trace of moisture. If this moisture is not well removed during the molding process, it will affect the bond strength of the film, which may cause the finished glass degumming and edging into the water.

In the process of installation, the process glass cannot be separated from the accessory materials such as edge sealant and glass glue. Customers are reminded that when using edge-sealing agent or glass glue, it is necessary to confirm that they have no staining and impregnation properties on EVA film materials, to prevent these accessories from adversely affecting the finished glass.

Special warning

Whether it is EVA film or other interlayer materials (such as photo paper), due to improper storage, there will be a "regain" in the rainy and humid weather.Sometimes there will be a layer of fine mist floating on the glass surface. If this "wet" phenomenon is not ruled out, the bonding strength of the tempered glass after processing will be greatly affected. Therefore, the customer is reminded to avoid the weather with high humidity as much as possible, and when it is necessary to produce, the film,the interlayer material and the glass must need to be"dried", which is good for improving the bond strength.